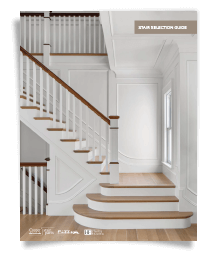

Since 1974 Cooper Stairworks has been blending centuries-old methods of stair building with state-of-the-art design and construction techniques allowing us to offer a complete stair system for the most selective buyers. Starting with the finest kiln dried lumber, we combine old world joinery, computers, innovative production equipment, and years of experience to create strong, beautiful, cost effective stairs.

Since 1974 Cooper Stairworks has been blending centuries-old methods of stair building with state-of-the-art design and construction techniques allowing us to offer a complete stair system for the most selective buyers. Starting with the finest kiln dried lumber, we combine old world joinery, computers, innovative production equipment, and years of experience to create strong, beautiful, cost effective stairs.

The preassembled staircase has long been considered the most efficient method of stair building. Its advantages of fast, accurate installation and jobsite labor savings are well respected throughout the industry. Cooper stairworks combines additional enhancements, adding still more advantages over site built stairs and exceeding the quality expectations of the most discerning craftsman.